Strategic metals productionh

Our development in the sector

Group companies in the sector:

Elemental Strategic Metals

In Zawiercie, in southern Poland, we built the second largest PGM metal refining facility in the European Union

Forecasts

Ultimately, the capacity to meet 70% of the EU’s needs for platinum group metals.

Production range

Pyrometallurgical processing of waste containing PGM metals – production of ferroalloys

Hydrometallurgical refining of PGM metals and production of pure Pt, Pd, Rh

Metal recovery technologies

Refining metals from catalysts

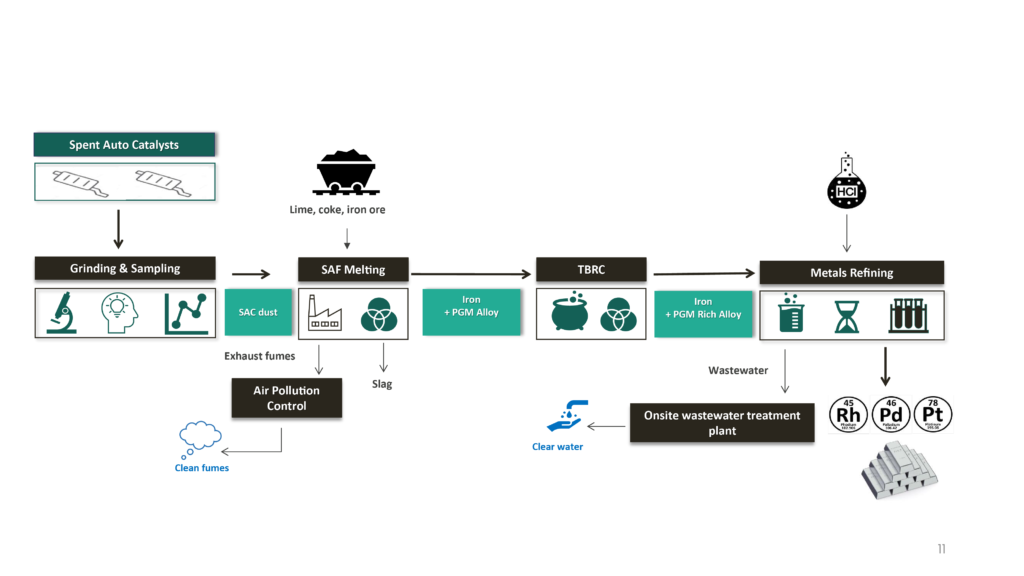

At the recycling stage, used catalysts from vehicles and industrial equipment are shredded and then processed using pyrometallurgical technologies, which allows for obtaining an alloy of iron with platinum group metals. Refining using hydrometallurgical methods is the final stage, thanks to which the following are recovered in metallic form: rhodium, palladium and platinum. Advanced technologies for environmental protection are important elements in the process.

Gases from technological processes pass through a system of scrubbers and filters, which guarantees their purity, and liquid waste goes to an advanced sewage treatment plant. The resulting side products, especially slag, are used as valuable raw materials in other industries. The processes do not generate hazardous waste and the equipment includes the necessary fire protection that meets the standards and needs resulting from the technological process.

PGM refining process

The Polvolt Project

What is Polvolt all about?

Elemental Battery Metals, as part of the “Polvolt” project, plans to build a plant producing critical raw materials (including lithium, cobalt, manganese, nickel and copper) especially for the battery and renewable energy industries.

For more information about the project visit www.elementalbatteries.com